About Our Company

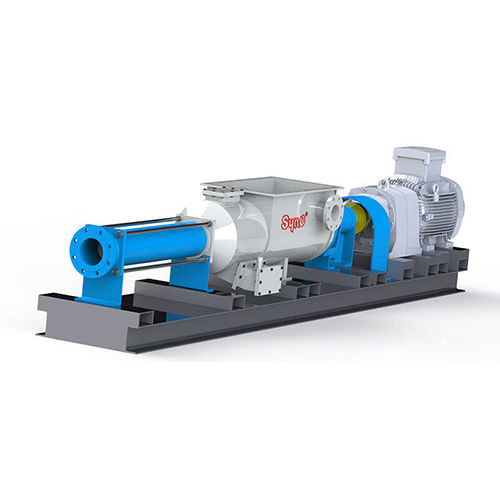

We as a Manufacturer & Exporter of Screw Pumps, Industrial Screw Pump, Chemical Pumps and Retrofit Spare Parts in India since 1975, offering a wide range of pumps serving worldwide Clientele in industries like Waste Water, Grouting, Pulp & Paper, Food, Sugar & Distillery, Pharmaceuticals, Oil, Power, Fertilizer and Chemical Industries etc.

At present, Syno Pumps is engaged in the industry as a manufacturer and exporter of an extensive range of pumps including Screw Pumps, Vertical Slurry Pumps, Sludge Pumps, Progressive Cavity Pumps, Industrial Pumps, Industrial Screw Pump, Chemical Pumps, Open Throat Pumps, Vertical Pumps, Small Multipurpose Pumps, Bore Hole Pumps, Hollow Shafts, etc.

Our Infrastructure

With decades of industry experience, Syno Pumps has established a robust infrastructure for itself. This machine shop is equipped with facilities for precision manufacturing Computerized Numerically Controlled (CNC) & Special Purpose Machine (SPM) and testing of products. The machine shop houses modern machines for rotor machining, milling centers, center lathes, radial drilling machines, vertical boring machines, horizontal boring machines, shapers, long thread milling machines, etc. We have our in-house polymer plant for manufacturing of stators and have machines like open roll mixing mill, hydraulic presses, extruders that assists us carrying out our business operations with ease and comfort. At our factory premise, we also have a sophisticated pattern shop and tool room to manufacture the complex steel cores for the stators, jigs and fixtures for better productivity levels and pattern shop for making of wooden or aluminum patterns required for casting purpose.

Participations